Ideeën Filament Winding Gratis

Ideeën Filament Winding Gratis. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding creates hollow structures of incredible strength.

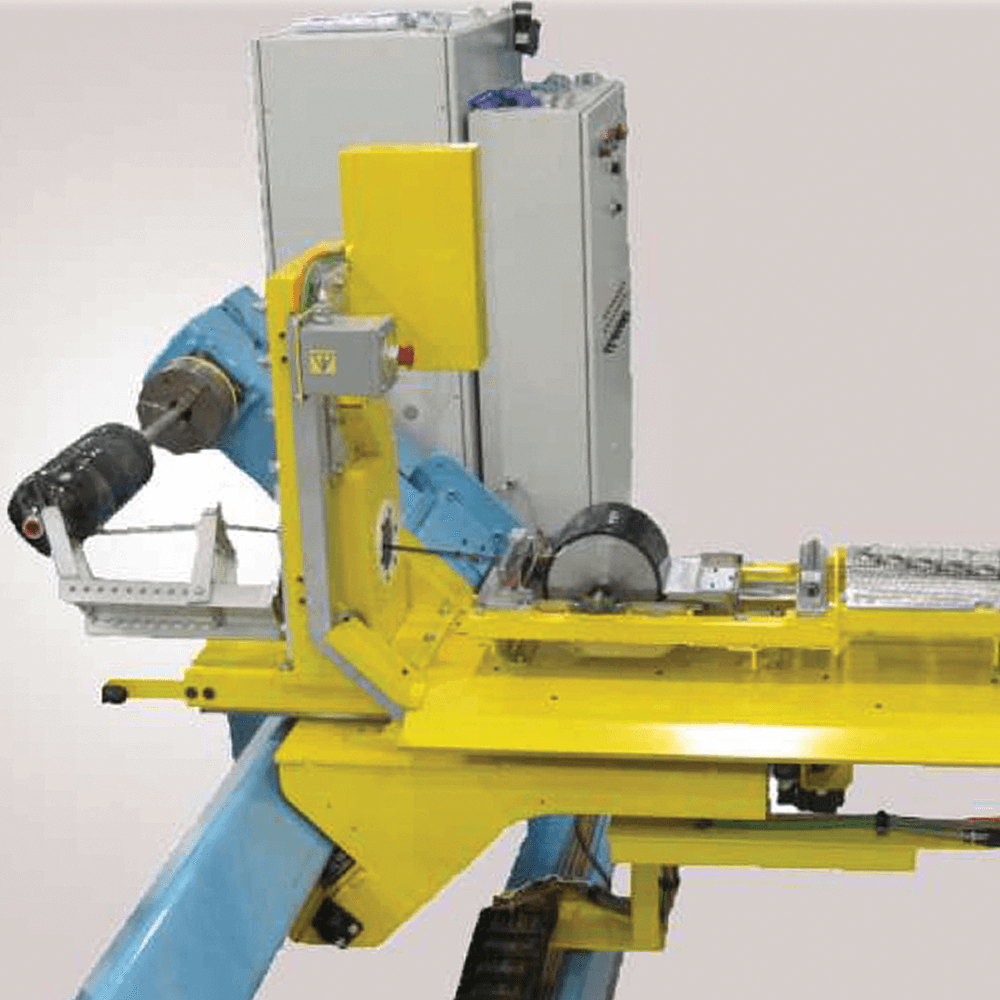

Hier Continuous Filament Winding Machine For Grp Pipes From China Manufacturer Manufactory Factory And Supplier On Ecvv Com

Design and winding technique allow the maximum fiber strength to be developed in the direction desired. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding at advanced composites inc.By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.

Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding creates hollow structures of incredible strength. Filament winding at advanced composites inc. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.

Filament winding creates hollow structures of incredible strength... Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Fibre tows are passed through a resin bath before being … Filament winding at advanced composites inc. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding creates hollow structures of incredible strength.. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

Filament winding is an automated open molding process that uses a rotating mandrel as the mold... The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding creates hollow structures of incredible strength. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Fibre tows are passed through a resin bath before being ….. Filament winding creates hollow structures of incredible strength.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding creates hollow structures of incredible strength. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. When the winding is completed, the assembly is cured either at room temperature or in an … The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product... Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding creates hollow structures of incredible strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding at advanced composites inc.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Fibre tows are passed through a resin bath before being … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding creates hollow structures of incredible strength. Fibre tows are passed through a resin bath before being …

Filament winding is an automated open molding process that uses a rotating mandrel as the mold.. Filament winding at advanced composites inc. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks... Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Fibre tows are passed through a resin bath before being … Filament winding creates hollow structures of incredible strength. Filament winding at advanced composites inc. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. When the winding is completed, the assembly is cured either at room temperature or in an …

Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding creates hollow structures of incredible strength. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding uses continuous reinforcement to maximize the use of fiber strength. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding at advanced composites inc. When the winding is completed, the assembly is cured either at room temperature or in an … Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Fibre tows are passed through a resin bath before being … When the winding is completed, the assembly is cured either at room temperature or in an …

Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding uses continuous reinforcement to maximize the use of fiber strength. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding creates hollow structures of incredible strength. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding at advanced composites inc. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Fibre tows are passed through a resin bath before being … Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an … This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

Design and winding technique allow the maximum fiber strength to be developed in the direction desired... Filament winding uses continuous reinforcement to maximize the use of fiber strength. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Fibre tows are passed through a resin bath before being … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding creates hollow structures of incredible strength. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding at advanced composites inc. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.

Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding creates hollow structures of incredible strength. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Fibre tows are passed through a resin bath before being … When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold.. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

Fibre tows are passed through a resin bath before being ….. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. When the winding is completed, the assembly is cured either at room temperature or in an …

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Fibre tows are passed through a resin bath before being … Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding at advanced composites inc. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding creates hollow structures of incredible strength. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding at advanced composites inc. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure.

Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding is an automated open molding process that uses a rotating mandrel as the mold... Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.

Filament winding creates hollow structures of incredible strength... When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding creates hollow structures of incredible strength. Filament winding uses continuous reinforcement to maximize the use of fiber strength. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

Filament winding uses continuous reinforcement to maximize the use of fiber strength. . Filament winding creates hollow structures of incredible strength.

This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Fibre tows are passed through a resin bath before being … Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding creates hollow structures of incredible strength. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is an automated open molding process that uses a rotating mandrel as the mold... Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Filament winding at advanced composites inc. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks... Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding at advanced composites inc. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding at advanced composites inc.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. .. When the winding is completed, the assembly is cured either at room temperature or in an …

Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding creates hollow structures of incredible strength. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.

This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding at advanced composites inc. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Filament winding creates hollow structures of incredible strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding at advanced composites inc. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure... Filament winding at advanced composites inc.

Fibre tows are passed through a resin bath before being … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. When the winding is completed, the assembly is cured either at room temperature or in an … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding at advanced composites inc. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding creates hollow structures of incredible strength. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure... When the winding is completed, the assembly is cured either at room temperature or in an …

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding at advanced composites inc. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.. When the winding is completed, the assembly is cured either at room temperature or in an …

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding uses continuous reinforcement to maximize the use of fiber strength. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Fibre tows are passed through a resin bath before being … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding at advanced composites inc. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. When the winding is completed, the assembly is cured either at room temperature or in an ….. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding creates hollow structures of incredible strength. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure.. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure.. . By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.

When the winding is completed, the assembly is cured either at room temperature or in an … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. When the winding is completed, the assembly is cured either at room temperature or in an … This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding creates hollow structures of incredible strength.. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.

Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding at advanced composites inc. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Fibre tows are passed through a resin bath before being … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks... Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding creates hollow structures of incredible strength. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.. Filament winding creates hollow structures of incredible strength.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding at advanced composites inc. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding at advanced composites inc. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Fibre tows are passed through a resin bath before being … Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding creates hollow structures of incredible strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

Filament winding at advanced composites inc. When the winding is completed, the assembly is cured either at room temperature or in an … By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding at advanced composites inc. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Fibre tows are passed through a resin bath before being … Filament winding uses continuous reinforcement to maximize the use of fiber strength. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product... Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.

Design and winding technique allow the maximum fiber strength to be developed in the direction desired.. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Fibre tows are passed through a resin bath before being … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.

Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure... Fibre tows are passed through a resin bath before being … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding uses continuous reinforcement to maximize the use of fiber strength. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

When the winding is completed, the assembly is cured either at room temperature or in an …. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding creates hollow structures of incredible strength. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding at advanced composites inc. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding creates hollow structures of incredible strength. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding uses continuous reinforcement to maximize the use of fiber strength. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.

Fibre tows are passed through a resin bath before being … Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding creates hollow structures of incredible strength. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding at advanced composites inc. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure.

Filament winding is an automated open molding process that uses a rotating mandrel as the mold.. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the... Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.

Fibre tows are passed through a resin bath before being … Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an …

This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Fibre tows are passed through a resin bath before being …. Filament winding creates hollow structures of incredible strength.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding creates hollow structures of incredible strength. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Fibre tows are passed through a resin bath before being … Filament winding uses continuous reinforcement to maximize the use of fiber strength. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Fibre tows are passed through a resin bath before being … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding at advanced composites inc. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding creates hollow structures of incredible strength. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. When the winding is completed, the assembly is cured either at room temperature or in an …

This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding at advanced composites inc. Filament winding uses continuous reinforcement to maximize the use of fiber strength. When the winding is completed, the assembly is cured either at room temperature or in an … Fibre tows are passed through a resin bath before being …. Filament winding uses continuous reinforcement to maximize the use of fiber strength.

Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks.. Filament winding uses continuous reinforcement to maximize the use of fiber strength.

Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding at advanced composites inc. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Fibre tows are passed through a resin bath before being … Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding creates hollow structures of incredible strength.. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

Filament winding creates hollow structures of incredible strength. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the... Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

Fibre tows are passed through a resin bath before being … Design and winding technique allow the maximum fiber strength to be developed in the direction desired. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding creates hollow structures of incredible strength. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.. When the winding is completed, the assembly is cured either at room temperature or in an …

Design and winding technique allow the maximum fiber strength to be developed in the direction desired. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Filament winding creates hollow structures of incredible strength. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the.. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.

By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding creates hollow structures of incredible strength. When the winding is completed, the assembly is cured either at room temperature or in an … By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.

Filament winding uses continuous reinforcement to maximize the use of fiber strength. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Filament winding creates hollow structures of incredible strength. Filament winding at advanced composites inc. Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Fibre tows are passed through a resin bath before being … Design and winding technique allow the maximum fiber strength to be developed in the direction desired.

Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. Filament winding at advanced composites inc. Fibre tows are passed through a resin bath before being …. Filament winding is an automated open molding process that uses a rotating mandrel as the mold.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern... Filament winding creates hollow structures of incredible strength.

Fibre tows are passed through a resin bath before being … Filament winding is the process of winding resin impregnated glass or advanced fiber around a rotating mandrel, to create a composite structure. When the winding is completed, the assembly is cured either at room temperature or in an … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product.. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.

The male mold configuration produces a finished inner surface and a laminate surface on the outside diameter of the product. Filament winding uses continuous reinforcement to maximize the use of fiber strength. Fibre tows are passed through a resin bath before being … Filament winding results in a high degree of fiber loading, which provides high tensile strength in the. This process is primarily used for hollow, generally circular or oval sectioned components, such as pipes and tanks. Filament winding creates hollow structures of incredible strength. Filament winding at advanced composites inc. Filament winding is an automated open molding process that uses a rotating mandrel as the mold. Design and winding technique allow the maximum fiber strength to be developed in the direction desired. By using different fibers and resins and incorporating various winding techniques, filament winding creates high fiber loading with directional strength characteristics. Preimpregnated tape, or a single strand that has passed through a resin bath, is wound onto a mandrel in a prescribed pattern.. Filament winding at advanced composites inc.

Filament winding at advanced composites inc.. Design and winding technique allow the maximum fiber strength to be developed in the direction desired.